|

|

|

|

专业销售美国RIEKER传感器、RIEKER倾角传感器、RIEKER电子罗盘、RIEKER陀螺仪、RIEKER加速度计 RIEKER陀螺仪工作原理:高速旋转的物体的旋转轴,对于改变其方向的外力作用有趋向于铅直方向的倾向。而且,旋转物体在横向倾斜时,重力会向增加倾斜的方向作用,而轴则向垂直方向运动,就产生了摇头的运动(岁差运动)。当陀螺经纬仪的陀螺旋转轴以水平轴旋转时,由于地球的旋转而受到铅直方向旋转力,陀螺的旋转体向水平面内的子午线方向产生岁差运动。当轴平行于子午线而静止时可加以应用。型号:SBS1U……

销售美国RIEKER传感器、RIEKER倾角传感器、RIEKER电子罗盘、RIEKER陀螺仪、RIEKER加速度计

产品图片 产品名称/型号 产品简单介绍

2056倾斜仪、角度水平仪、2056E倾角传感器,系列Rieker倾角水平仪,升降天车、起重机手臂、水平测量、

2056水平仪/2056E倾角水平仪/倾斜仪 Manual Inclinometer: Model 2056E Commonly referred to as

a Clinometer (as in typical marine applications like boating) Two (2) scales,

two (2) ranges Top Scale gives accurate 1º readings - usef

起重、吊车、挖掘机、机械手臂角度指示仪、倾角传感器

4120L 臂角指示器:型号4120、4120WWL、4120WWL- 12V 吊车手臂指示仪、背光为较高的亮度,在光线不足的或夜间操作(无背光可选)

符合美国国家防火协会(NFPA)1901年用于汽车消防设备标准: 20.4云梯操作位置 工作温度:-50° F至+180° F 坚固的聚碳酸酯制造安装容易

4120一般规格手册 型号4120 WWL- 12V Specificaitons

RDS7 - BB 数字球倾斜仪

RDS7 - BB 数字球倾斜仪 倾角传感器 瑞可 根据从交通和运输部工程师Rieker推出了领先的RDS7 -

BB的球倾斜仪行业的最新版本全国反馈。在-09版本允许运营商之间切换观看的度数或百分比等级的角度。它还提供了输入功率的车辆(8 30V直流非经DSUB连接器调节)没有点烟器插头插座或永久硬接线线路的解决方案。

最主要的特色 - 现在的标准 - 是能够调整行程的± 10 °角度设置到适当的角度,指出在贵国的通过MUTCD(设置安全曲线

球形倾斜仪 1023W1

银球指示:手动及电子 1023W1

所谓“银球指标”是指一种可以被用于确定安全水平曲线(统一咨询)曲线速度倾斜的具体用途。它的措施倾覆力(侧面摩擦),在谈判一平曲线车辆度测量, -

无论它是一个孤立的曲线,多“S”曲线,或从高速公路匝道为/。通常由交通运输部和其他咨询机构。

姿态指示仪 专门为俯仰和滚动用于倾角在加油或装载平衡负载。

姿态指示仪 专门为俯仰和滚动用于倾角在加油或装载平衡负载。 这些专门为俯仰和滚动用于倾角在加油或装载平衡负载。

美国联邦航空局认证的样本指标和美国太平洋海运协会专利授权。 Rieker生产各种指标的态度为OEM飞机燃料系统的校准(也称为一个测斜仪)。以下是美国联邦航空局的型号认证的模式。我们的态度指标已作为原始设备上安装了许多飞机在生产阶段,或作为售后市场的升级,以取代老式的'铅锤的系统购买。

瑞可加速计 加速计:线性静态和动态

瑞可加速计 加速计:线性静态和动态 加速计:线性静态和动态

定义:加速度计是一种测量加速度,振动检测和测量,或测量重力加速度(倾角)的工具。加速度传感器可用于测量车辆,机械,建筑,过程控制系统和安全装置的振动。它们也可以用来衡量有或没有重力影响的地震活动,倾斜,机械振动,动态距离和速度。

精密机械背光倾角仪 背光倾角指示仪

背光倾角指示仪 说明 同样高的质量,从Rieker预期一个新的创新技术,即光管(非住宅),这样你可以清楚地看到球的位置。可与客户指定的住房或颜色最佳能见度管区。

这些引人注目的背光模型,专门用于消防车辆所需的所有仪器都点燃 - 1017和1023型号符合国家消防协会1901年标准的汽车消防设备

不过,这些都是非常适合任何行业,当仪器必须在低光或夜间操作可见。可用于单件和OEM量的一致好评。

H4系列坚固倾角传感器

H4倾角传感器 倾角传感器 H4的测斜仪可提供准确的倾斜在一个坚固的锌金属感应,保护环境的外壳。 该H4A提供模拟电压0 -

5V的输出,H4S提供了一个数字串行RS232输出。都有两种温度补偿金额可供选择,这取决于工作温度,提高在整个温度范围内精度。

外壳是专为在现场改造,无需重新安装孔钻(中心与滑块法兰常见的位置)。

产品图片 产品名称/型号 产品简单介绍

HLR750系列 防爆LVDT,ATEX防爆认证,UL/CE认证,GE公司汽轮机认证,UL/ULC Listed for Class 1, Division

HLR750-1000,HLR750-20000,HLR750-5000 HLR 750系列是3/4英寸直径、高可靠性LVDT是特别为汽轮机的使用环境而设计。这种额定使用温度为300°F

(150°C)的气密封交流供电LVDT可以满足 ATEX防爆A、B、C、D组,第2章,第1级 及IIC组,第2节,第1级长所述的危险环境认证。全不锈钢结构、过孔设计使LVDT的铁芯容易所两端得到更好的机械支持及铁芯导引,并且在污积秽环境容易清洁。获得

CD 375 微型LVDT位移传感器 高温105度 高压140mpa LVDT位移传感器

cd375 cd375-100 cd375-200 cd375-050 cd375-2000 位移传 马克罗传感器

推出的CD375系列是3/8英寸(9.5毫米)直径、交流供电的小型非接触式线性位移传感器,既能满足OEM客户的应用,也能满足终端用户的要求。CD 375

LVDT,CD375 微型LVDT位移传感器 耐高压140mpa LVDT位移传感器

PRH 812 通用线缆*流 位移传感器 LVDT

prh812 prh812-1000 prh812-1000-0135 macro sensors位

可选量程从±0.050英寸(±1.25毫米)至±10英寸(±250毫米),提供一个铁芯-内孔径向间隙为0.062英寸(1.6毫米)、铁芯直径为0.25英寸(6.35毫米)的标准铁芯。PR

812系列传感器具有分辨率高、重复性好、阻抗低、灵敏度高、线性好等LVDT技术特征。任何这种传感器的最大线性误差都不超过满量程输出的±0.25%最佳直线法

BBP 315超高精度微型 位移传感器 macrosensors BBPM315超小型位移传感器

BBP 315 马克罗传感器公司推出的 BBP系列8毫米直径铅笔式测量头为广泛的质量控制 、SPC及

工业度量应用提供超高精度的测量。它们用直线滚珠轴承与硬化、非旋转测量轴精密组合

,将径向游隙及边缘荷载的影响最小化。使测量头的重复性达到0.000006英寸(0.15微 米)。

GHSI 750 LVDT 位移传感器 回弹轴向密封型直流 4-20mA输出 GHSI750位移变送器

GHSI750 LVDT 磁致伸缩位移传感器 Macro Sensors GHESI750系列LVDT位移变送器

传感器公司推出的GHSI750系列直径为3/4’’回弹式回路供电LVDT位置变送器广泛适用于位置监测、反馈和尺寸计量。该系列传感器坚固、密封,完全采用不锈钢材料,满足一般工业用途。为抵御各种恶劣环境,线圈绕组采用密封封装,达到IEC

IP-68防护等级。输入/输出连接穿过密封轴向接头。0-10输出可选:GHSE750系列位移传感器

PR 812 通用线缆型交流 位移传感器

pr812-1000 pr812-1000-0135 pr812 可选量程从±0.050英寸(±1.25毫米)至 ±10英寸(±250

毫米),也提供一个铁芯-内孔径向间隙为0.031英寸(0.75毫米) 的标准铁芯。PR 812系列传感器具有分辨率高、重复性好、阻抗低、灵敏度高、线性好等LVDT技术特征。任何这种传感器的最大线性误差都不超过满量程输出的±0.25%最佳直线法。

Accelerometers:

Linear Static & Dynamic

|

|

|

Definition

An

accelerometer is an instrument for measuring acceleration,

detecting and measuring vibrations, or

for measuring acceleration due to gravity (inclination).

Accelerometers can be used to measure vibration

on vehicles, machines, buildings, process control systems and

safety installations. They can

also be used to measure seismic activity, inclination, machine

vibration, dynamic distance and speed

with or without the influence of gravity.

Introduction

Rieker’s line of accelerometers (see comparison chart below) are

available in single, dual, or tri axial packages, with a variety

of frequencies and G ranges to suit many different test and

control applications. These accelerometer sensors are small

capacitive spring mass based with integrated electronics, which

do not require external amplifiers, providing for a very high

resistance to extreme acceleration overloads and

shocks. Available with Analog DC, digital Pulse-Width Modulated

(PWM) or frequency- modulated outputs.

|

|

Features

-

Low Cost, Light Weight,

Compact

-

Hermetically Sealed

-

Operational

from -40°C

to +125°C

-

10,000 g impact & shock

resistant

-

Static DC

-

150 - 1500 Hz bandwidth

-

Dynamic

accelerometer with

low 1Hz corner frequency

-

Low noise

|

Accelerometer Sensors

(Single Axis)

|

Model |

Ranges |

Resolution |

Sensitivity |

Non-Linearity |

Output |

Supply

Voltage |

Dimensions

inches [mm] |

Bandwidth |

|

B1 |

±3g |

<0.001g |

100 mV/g |

<0.2% FS |

UbN = 5

Volt |

3 . . 6 VDC |

Ø

0.93" x 0.43"

[Ø 24 x 11] |

0 . . 160 Hz |

|

B2 |

±10g |

<0.005g |

23 mV/g |

0 . . 350 Hz |

|

B3 |

±50g |

<0.010g |

6.5 mV/g |

0 . . 550 Hz |

|

BDK3 |

±3g |

<0.001g |

150 mV/g |

<1% FS |

UbN = 5

Volt |

2 . . 16VDC |

Ø

0.87"

x 0.4"

[Ø 22 x 10] |

1 . . 300 Hz |

|

BDK10 |

±10g |

<0.005g |

60 mV/g |

1 . . 800 Hz |

|

BDK100 |

±100g |

<0.050g |

10 mV/g |

1 . . 1500 Hz |

|

Tri-axial Accelerometer / Inclinometer Package |

|

SBG3i |

Based on Sensor Model |

Based on Sensor Model |

Based on Sensor Model |

Based on Sensor Model |

4-20mA |

8 . . 30 VDC |

4.9" x 3" x 2.25"

[123 x 78 x

58] |

1 . . 1500 Hz |

Mounting Cubes

(Dual or Tri-Axial)

|

|

BS24

Compatible with:

• NB3 Inclinometer

• B1, B2, and B3 Accelerometer |

|

SW3

Compatible with:

•

N or NB3 Inclinometer

• B or BDK Accelerometer |

|

Attitude Indicators: Aircraft Fuel System

Calibration

|

Definition

Specialized Pitch & Roll

Inclinometers for balancing loads during fueling or loading of

Commercial Aircraft

Introduction

manufactures a variety of Attitude Indicators (also known as an

Inclinometer) for OEM Aircraft Fuel Systems Calibration. Several

models must carry FAA certification for use on specific

Commercial Aircraft.

Our Attitude Indicators have been

installed as original equipment on many aircraft at the

manufacturing stage, or purchased as an aftermarket upgrade to

replace older style 'plumb bob' systems.

|

Part Number 5002P, FAA Certified Pitch Indicator |

Attitude Indicator Models

|

|

1017S5*

5002P*

5002R*

5005* |

A25-1

A25-3 |

A500

A502

A503

A505 |

|

* FAA Type Certified under our PMA

licensing agreement and ship with appropriate FAA documents. |

|

Backlit Inclinometers:

Mechanical "Ball-in-Tube" Type

|

|

|

Description

These highly visible backlit models were specifically developed

for fire trucks that are required to have all instrumentation

lighted

models 1017 (±10º) and 1023 (±20º) comply with National Fire

Protection Association 1901 Standards for Automotive Fire

Apparatus.

However, these are well suited for any industry when

instrumentation must be visible in low light or night operation.

Available in single piece and OEM volumes alike.

Also

referred to as a clinometer or ball in tube level, the "-12VT"

models are

backlit versions of our precision inclinometers that have been

in the field for decades.

Same high quality expected from Rieker, with a new innovative

technique that lights the tube (not the housing) so you can

actually see the ball position. Available with customer

specified color zones on the tube for best visibility.

Equipment Types

Aerial lift trucks, Bucket/utility trucks, Cranes, Construction

Equipment, Conveyor and Material Handling Equipment, Emergency

and Fire trucks, Government and Military Vehicles, Trailers.

Contact us today for a quote. OEMs welcome, quantity pricing

available.

If you have an

application that requires custom specifications,

please contact us today

with your requirements. One of our engineers will be happy

to speak with you. |

Photo

Above:

1023SPL3-8/12/20-12VT

Features

-

Long lasting Bright White LED Integrated into Existing

Housing.

-

Max current draw approx. 40mA at max input voltage.

-

Standard 12VDC or 24VDC input supply voltage (8-30VDC).

-

Same ALL-weather performance.

-

Same Precision Glass for Clear Viewing AND Best Ball Roll.

-

Same Rugged Die-Cast Aluminum Housing.

-

Same Customer Specified Color Warning Zones - easy to see

quick reference of safe or danger zones - on tube for best

visibility!

-

Same Operating Temperature

-40ºF to +160ºF

Applications

-

Quick and Accurate Visual Reference

for Low Light or Night Operation

-

Leveling, Balancing and helps Prevent Tip-over

-

Machining or Anywhere Precise Leveling Required

|

|

| |

Ball Bank Indicators: Mechanical and Digital

|

MechanicalBall Model 1023W1

Electronic

Digital Model RDS7-BB-09

|

|

Description

Rieker Ball

Bank Indicators reflect the operating procedures of Federal,

State, and local roads and highways, based upon the “Speed Zone

Theory” and “85th Percentile Speeds”, which is adapted by the

American Association of State Highway and Transportation

Officials (AASHTO); Institute of Transportation Engineers

(ITE) and as defined in the Federal and/or State Manual of

Uniform Traffic Control Devices, (MUTCD). Rieker

indicators have been the ball bank standard instruments used by

Federal and State Departments of Transportation Nationwide since

the 1950's. |

|

Definition

The term "Ball

Bank Indicator" refers to an inclinometer (or Accelerometer used

as an inclinometer) that is used for the specific purpose of

determining safe (uniform

advisory)

curve speeds

for

horizontal curves.

It

measures the overturning force (side friction), measured in

degrees, on a vehicle negotiating a horizontal curve.

If you have an application that

requires custom specifications,

please

contact us today with your requirements. One of our

engineers will be happy to speak with you. |

|

Mechanical Inclinometer:

1023W1 "The Original" Ball Bank

Indicator

-

±20º Inclinometer

-

The Original Inclinometer Used by DOTs

for Determining Safe Curve Speed Since the 1950's

-

1º Increments for Increased Accuracy,

smooth properly damped ball roll for precise real time readings

-

Quick Visual Reference, Early Warning

Indicator (ie Roll Over)

-

1000 Series Brochure

|

|

|

Model 1023W1 Specifications |

|

Dimensions |

5 3/8"w X 1 3/4"h X 5/8"d |

|

Degree

Range |

±20° |

|

Degree

Markings |

1° |

|

Case

Materials |

Black painted aluminum, engraved markings filled

white |

|

Tube

Construction |

Glass with black ball on white background |

|

Digital Ball Bank Indicator

|

Overview

The RDS7-BB Digital Ball

Bank Indicator has been the DOT adopted standard electronic

measuring device for determining safe curve speed since the

1990's. The "-09" version allows the operator to adjust the

trip angle setting to the appropriate angle as indicated in

your State's adopted MUTCD (for setting safe curve speed

based on road type and MPH).

|

Features

-

Single Axis Measurement

- Adjustable LED (visual)

and Buzzer (audible) trip angle settings

- Buzzer on/off

- Cigarette Lighter Adaptor

- Angle measuring range ±30º

- LCD Display Resolution

0.1º

- RS232 output via serial

port connector (cable supplied)

- Easy installation

- Portable for multi-vehicle

use

- Simple display interface

|

Applications

- Safe Curve Speed Studies

- Ball-banking

- Vehicle Roll Monitoring

Industries

- DOT

- Public Works

- Accident Investigation

- Road and Transportation Construction

- Civil Engineering

|

|

Boom Angle Indicators:

Digital Remote LCD & Mechanical

|

|

|

All

cranes, derricks and certain lift equipment require some form of

boom angle indication. Boom angle indicators must be visually

readable by the operator. |

|

Mechanical

Boom Angle Indicator

Rieker 4120 Series of rugged ALL-Weather

Mechanical Boom Angle Indicators. |

Digital Boom Angle Indicator

Rieker RDSR3-BA-09 Digital LCD Display Remote

electronic boom angle indicator is sealed in a rugged case that

protects the sensor components from harsh environments. |

An inclinometer utilized for boom angle indication typically has

a degree range of -10 to +90 degrees to accommodate a variety of

boom types. The capacities that are listed on the crane load

charts are also based on and vary with the boom angle of the

crane.

For example: On hydraulic cranes, the boom angle is the angle

between the bottom of the boom butt and the horizontal while the

boom is under load (fig 1, view A). The boom angle on lattice

boom cranes is the angle between center line of the boom (from

the boom butt pins to the boom tip sheave) and the horizontal

while the boom is under load (fig 1, view B)

Figure 1

To check the accuracy of the boom angle indicator, place a

3-foot builders level on the center boom section and raise or

lower the boom until the level indicates the boom is level. At

this point the boom angle indicator should show the boom is at

zero degrees or adjusted to read zero degrees. |

|

Rieker Boom Angle Indicators

comply with current OSHA Standard 1926.550

|

OSHA -

Occupational Safety & Health Administration / U.S.

Department of Labor

-

Part

Title: Safety and Health Regulations for

Construction

-

Subpart Title: 1926 Subpart N: Cranes, Derricks,

Hoists, Elevators, and Conveyors

...1926.550(g)(3)(ii): Instruments and Components

......1926.550(g)(3)(ii)(A): Cranes and derricks with

variable angle booms shall be equipped with a boom angle

indicator, readily visible to the operator.

Click the

link below to visit the OSHA web site> |

|

|

Boom Angle Indicators:

Mechanical Type 4120 Series

|

|

|

|

|

|

|

4120WWL |

4120BBL |

4120WBL |

4120WWL-12V* |

|

Description

Rieker's rugged ALL-Weather Mechanical Boom

Angle Indicators are not affected by outdoor elements. These

instruments are made tough and will not rust, freeze, or

otherwise "hang up" like old fashioned pendulum style boom angle

indicators.

Like all of our instruments, each boom angle

indicator is properly damped for smooth reliable

readings. Designed for easy mounting with two screws for quick

and efficient retro-fitting in the field.

4120 Specification Brochure

(PDF)

*Available in a highly

visible backlit model for

increased safety - complies with National Fire Protection

Association 1901 Standards for Automotive Fire Apparatus.

Please note:

A

boom angle indicator is a quick reference for the operator.

The capacities that are listed on the

crane load charts are also based on and vary with the boom angle

of the crane. However, do

NOT rely on the boom angle indicator for radius accuracy

especially when the lift exceeds 75 percent of the rated

capacity. Use the radius measurement to determine the capacity

of the crane from the load charts and to avoid any possibility

of error.

4120 PART Numbers for

ordering |

Features

-

Oversized inclinometer with High Visibility

Markings - large numbers for easy read

-

Hermetically sealed - assures dust free

smooth and accurate reading

-

Weatherproof - will not rust or hang up

-

100% Polycarbonate Construction - direct

impact, shock, and vibration resistant

-

Easily installed - retrofit in the field,

only 2 screws needed

-

UV Resistant - fade resistant

-

Operational from -50° F to +180° F - will

not freeze or hang up

-

Right hand (R) or left hand (L) models

available - read from either side of boom

|

|

Left

Side Boom Mount

4120WWL

4120WBL

4120BBL

4120WWL-12V |

|

Right

Side Boom Mount

4120WWR

4120WBR

4120BBR

4120WWR-12V

|

|

Boom Angle:

RDI Digital LCD Boom Angle Indicator

|

|

All cranes,

derricks and certain lift equipment require some form of boom

angle indication. Boom angle indicators must be visually

readable by the operator. |

|

Rieker Boom Angle and Tilt / Level Indicators Comply with

Current OSHA Standard 1926.550 |

|

Model RDSR3-BA-09 General Specifications |

Features

- Nema 4 rugged Aluminum housing

- Industrial Temperature Compensation over -40/+85ºC

- Angle range -10 to +90º

- Backlit LCD Display Resolution of 0.1º

- Adjustable LED trip settings

- 8-30VDC non-regulated supply

- Military Style Amphenol Circular Connectors for

interface cable

- Remote box has mounting feet for easy field

installation and zero calibration

- Relative "Temporary" Zero

- Comply with Current OSHA Standard 1926.550

|

|

Description

Rieker's Digital Boom Angle

Indicator Remote Inclinometer Package (model RDSR3-BA-09) is an

extension of the RDI series of digital inclinometers.

Like the 4120, our electronic

boom angle indicator is sealed in a rugged case that protects

the sensor components from harsh environments. The RDSR3 is

supplied as a calibrated set featuring an environmentally sealed

measurement sensor package and a separate LCD display box

(connected by an interface available in various lengths). All of

the standard RDI features have been incorporated into this

remote sensing package, modified specifically to comply with

OSHA and other safety regulatory agencies specifications for

Boom Angle Indicators.

The display model comes standard

with green, yellow, and red LED lights (with adjustable trip

setting) provide the operator a bright fast visual warning of

safe and unsafe operating conditions. The green light indicates

safe operating zone, yellow as the early warning, and red as the

danger zone. An optional audible alarm model is also available -

the red LED on the front panel display is tied directly to the

buzzer.

The RDSR3-BA-09 comes standard

with Relative Zero and Min/Max Angle functions. The Relative

Zero allows the operator to temporarily zero the digital readout

to obtain relative slope changes. The Min/Max function provides

the smallest and largest angle since the last reset.

Please note: A

boom angle indicator is a quick reference for the

operator to know what angle the boom is at.

The

capacities that are listed on the crane load charts are also

based on and vary with the boom angle of the crane.

However, do NOT rely on the boom angle indicator for radius

accuracy especially when the lift exceeds 75 percent of the

rated capacity. Use the radius measurement to determine the

capacity of the crane from the load charts and to avoid any

possibility of error. |

|

Total Solutions:

Curve Advisory Reporting Service (CARStm)

|

Introduction

Rieker Inc., the leader in ball-bank instruments, introduces for

2015 the only complete service for establishing uniform safe

advisory safe curve signage at a State-wide level.

SAFETY FIRST

- Allows driving with traffic - any

speed. CONSISTENCY

- Meets FHWA 2009 MUTCD requirements.

ON-TIME Project Completion

- saves man hours & budget.

Now available through authorized fully trained and certified

service providers - complete turnkey to project based solutions.

If interested in becoming an Authorized

CARS Provider call today to speak with one of our CARS Solutions

experts.

Call us today to find the service provider in your state -

610-500-2000 - and learn how

Rieker CARS Solution will help you meet the FHWA mandate for

re-surveying all required roadway horizontal curves by 2019. |

Description

The Curve

Advisory Reporting Service (CARS™) automatically captures

all road data needed - in just one pass with traffic. Then

auto-uploads to the CARS online app for automated Horizontal

Curve Advisory Speed Reporting.

Rieker

CARS service reflects the operating procedures of Federal,

State, and local roads and highways, based upon the “Speed

Zone Theory” and “85th Percentile Speeds”, which is adapted

by the American Association of State Highway and

Transportation Officials (AASHTO); Institute of

Transportation Engineers (ITE) and as defined in the Federal

and/or State Manual of Uniform Traffic Control Devices, (MUTCD).

CARS Media:

|

CARS

Service Features

-

Safe & Continuous Operation

-

1

Pass each direction!

-

With Traffic!

-

FHWA

Compliant

-

Meets Federal MUTCD Requirements

-

Integrated GPS

-

Key Data Collection

-

Cloud Reporting

-

Automatic upload of survey data

-

Software allows review of detailed road

survey data

-

Generates reports for recommended curve speed

-

Allows for customization of horizontal limits

to meet individual State requirements

-

Secure

Online

Data Storage

-

Automated Curve Speed Calculations

|

|

Circular Bubble

Levels: Precision "Bulls-Eye"

|

|

|

|

|

Description

Also referred to as a

“bulls-eye” level, the C000X Series of Circular Bubble Levels

provide accurate measurement of level in a rugged machined

Aluminum housing (Anodized black). Several sizes available to

fit any space requirement.

Manufactured to exacting specifications, the

accuracy is guaranteed and maintained through the use of

precision ground glass and machined Aluminum.

Rigorous testing

completed to assure high performance over long-term all weather

conditions, including industry

standard ASTM Salt

Fog survivability.

Each instrument is filled with

a special damping fluid that controls the movement of the

bubble, for smooth accurate readings. The fluid combined with

large, clear markings make it easy to get quick, accurate

readings under a wide variety of severe environmental

conditions.

These precision circular vials

have three mounting holes for installation convenience and

calibration. Since most mounting surfaces may vary, for exact

zero calibration the C000X-A models all come with mounting

hardware.

Contact

us today for a quote. OEM quantity pricing available.

If you

have an application that requires custom specifications,

please

contact us today

with your requirements. One of our engineers will be happy

to speak with you. |

Features

Applications

-

Quick Accurate Visual Level Reference

-

Leveling, Balancing and Preventing Tip-over

-

Machining or Anywhere Precise Leveling

Required

Equipment Types

-

Aerial

lift trucks

-

Bucket/utility trucks

-

Cranes

-

Construction Equipment

-

Conveyors

& Material Handling

-

Fire

Aerial Ladder Rigs

-

Government

and Military Vehicles

-

Recreational Vehicles (RV)

-

Trailers

|

|

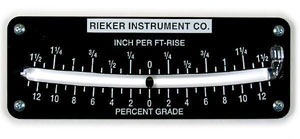

Gradiometers: Mechanical

& Electronic Digital LCD Display

|

|

|

Model 5012P |

Model 2064EGM |

RDI

Digital Inclinometer Series

|

|

Mechanical "Ball-in-Tube" Type

Gradiometers |

Digital LCD Display Type |

Description

These precision instruments aid

the operator with quick visual indication of grade or slope.

Applications include bull dozers,

excavators, motor graders, pavers, plows, trenchers or other

equipment. The

digital version (RDI Series) can also be used to monitor

and control equipment.

If you have an application that requires

custom gradiometer specifications,

please contact us today

with your requirements. One of our engineers

will be happy to speak with you.

|

Definition

A Gradiometer - another type of inclinometer

- is used to accurately determine any slope or grade angle

quickly and easily. These precision instruments provide

accurate readings in either percent grade, degrees of

inclination, or inch per foot rise. |

|

Inclinometers:

Mechanical & Electronic

|

|

|

|

Mechanical |

Electronic |

|

Mechanical Inclinometers |

Inclinometer Sensors & Accelerometers |

Digital LCD Display Inclinometers |

|

|

|

|

|

Precision

"ball-in-tube" Clinometers

Slip Indicators

Custom Tubes

Color

Warning Zones

Backlighting |

Single & Dual Axis

0-5VDC

0-10V

4-20mA

RS232

RS485

PWM |

Digital LCD Display

Remote Angle Monitoring

with

Analog(0-5V), Digital Serial (RS232), and Switch Outputs |

Inclinometer is an instrument for

measuring angles of slope and inclination of an object with

respect to its gravity by creating an artificial horizon. It is

also known as a tilt sensor, tilt indicator, slope meter, slope

gauge, gradient meter,

gradiometer, level

gauge & level meter. An inclinometer is commonly used in

different industries like

Aviation, civil

engineering, Government, Marine, Military, and Transportation

for platform

leveling, boom angle indication and slope angle measurement. The

tilt angle range is the range of desired linear output measured

in degrees. Important specifications to consider when searching

for tilt sensors and inclinometers are the tilt angle range and

number of axes.

|

If you have an application that

requires custom specifications,

please contact us today

One of our engineers will be happy

to speak with you.

Product Summary Catalog

Full Product Catalog |

|

Mechanical Inclinometers: Precision

"Ball-in-Tube" Type

|

|

|

|

|

|

Inclinometer Model

1017SPL3-3.5/8/10 |

Gradiometer Model

2064EGMSPL-A |

Boom Angle Indicator Model

4120BBL |

|

Description

Rieker manufacturers

mechanical inclinometers using precision glass

or Polycarbonate tube and ball

construction with engraved or silk screened markings. Certain

models are available with customer specified color

warning zones. All our tubes are filled

with a special damping fluid that controls the movement of the

ball. The fluid combined with large, clear number and degree

markings make it easy to get quick, accurate readings under a

wide variety of severe environmental conditions.

Custom Color Zones

The color zone or "SPL" models are designed to instantly alert

the operator of tip-over danger utilizing highly visible color

zones: e.g. RED = tip-over danger; GREEN = safe operation. The

color zones are based on degree settings specified by the

customer - these must be specified at time of order. 1, 2 or 3

color zones available in Green, Yellow, and/or Red.

If you have an application requiring custom specifications,

please

contact us today - one of our application experts will be

happy to speak with you.

|

Features

Applications

-

Quick Visual of Angle

-

Platform Level

-

Roll Over

Early Warning

-

Slope

Indication

-

Percent

Grade

Equipment

-

Aerial Ladder Rigs

-

Aerial Lift Trucks

-

Aircraft

-

Barge

Cranes

-

Boom

Trucks

-

Construction Equipment

-

Cranes

-

Fire

and Rescue Trucks

-

Government Vehicles

-

Graders

and Excavators

-

Marine

Vessels

-

Military Equipment

-

Offshore

-

Sail

Boats

-

Submarines

-

Utility Trucks

|

Mechanical

Inclinometer Part Numbers:

|

Model |

Degree Range |

Degree

Increments |

Dimensions (w x

h x d) |

|

1005 |

±5° |

0.5° |

6"

X 1 5/8" X 5/8" |

|

1017 |

±10° |

2° |

6"

X 1 5/8" X 5/8" |

|

1017S5* |

±5° |

0.5° |

6"

X 1 5/8" X 5/8" |

|

1017W1 |

±10° |

1° |

6"

X 1 5/8" X 5/8" |

|

1017SPL2 |

±10° |

2° |

6"

X 1 5/8" X 5/8" |

|

1017SPL3 |

±10° |

2° |

6"

X 1 5/8" X 5/8" |

|

1023 |

±20° |

5° |

5

3/8" X 1 3/4" X 5/8" |

|

1023N |

±20° |

1° |

5

3/8" X 1 3/4" X 5/8" |

|

1023W1 |

±20° |

1° |

5

3/8" X 1 3/4" X 5/8" |

|

1023SPL2 |

±20° |

5° |

5

3/8" X 1 3/4" X 5/8" |

|

1030 |

±10° |

1° |

4

1/2" X 1 1/2" X 7/8" |

|

1030SPL |

±10° |

1° |

4

1/2" X 1 1/2" X 7/8" |

|

1040* |

±10° |

5° |

2

9/16" X 1 1/8" X 1/2" |

|

2055 |

±60° |

5° |

6"

X 2 1/2" X 3/8" |

|

2055E |

±60° |

5° |

6"

X 2 1/2" X 3/8" |

|

2056 |

upper scale ±6°

/ lower scale ±60° |

upper scale 1° /

lower scale 5° |

6"

X 3 3/4" X 3/8" |

|

2056E |

upper scale ±6°

/ lower scale ±60° |

upper scale 1° /

lower scale 5° |

6"

X 3 3/4" X 3/8" |

|

2058 |

±45° |

±10° in 2½°

Increments

±10° to

45° in 5° Increments |

6

1/2" X 2 3/8" X 3/8" |

|

2058E |

±45° |

±10° in 2½°

Increments

±10° to

45° in 5° Increments |

6

1/2" X 2 3/8" X 3/8" |

|

2064EM |

±26° |

2° |

6"

X 2 3/8" X 3/8" |

|

2064EGM |

±26° |

2°,

(5%) |

6"

X 2 3/8" X 3/8" |

|

2064EGMSPL |

±26° |

2°,

(5%) |

6"

X 2 3/8" X 3/8" |

|

490 |

-10° through

+80° |

5°

(right or left orientation) |

6"

X 2 11/16" X 3/8" |

|

4120 Series** |

-30° through

+90° |

5°

(right or left orientation) |

14"

X 6 3/8" X 1 3/4" |

|

5012P |

±13% Grade ±1.5

Ft/Rise |

1%

(1/8 FT/Rise) |

8"

X 2 7/8" X 3/8" |

*FAA Type

Certified under our PMA licensing agreement and ship with appropriate

FAA documents.

**Backlit

for better visibility, specifically for low light or night use. |

Electronic Inclinometers:

Tilt & Acceleration Sensors

|

|

|

Description

Rieker provides a complete line of inclinometer

and accelerometer sensors. These sensors

are used for vehicle tilt monitoring, slope measurement, boom

angle indication, hydraulic motion control, wheel alignment,

vibration indication, and pitch & roll measurement. Semi-custom

and custom products available, contact us today to discuss your

needs.

The electronic inclinometer sensors are gravity

based with no moving parts and nothing to break - very reliable

for rugged applications.

Rieker also manufactures a versatile series of

digital inclinometers with LCD display, multiple outputs

(including analog, digital and switch) making it the most

customizable angle monitoring and early warning tilt indication

system on the market today. |

INDEX

Related Documents

|

Inclinometer Sensors

|

Series |

AXIS |

Range |

output |

input

supply |

IP rating |

dimensions |

|

H4 |

SINGLE |

up to 360º |

0...5V, RS232,

4...20mA,

RS485 |

8...30VDC |

67 |

Ø 1.95" x 1.1"

[Ø

49.6 x 28] |

|

H5 |

SINGLE |

up to ±90º |

0...5V, 0...10V,

RS232 |

12...30VDC |

67 |

Ø 2.52" x 1.1"

[Ø

64 x 28] |

|

H6-Flex |

DUAL |

scalable |

4...20mA,

RS485, CAN |

11...30VDC |

68 |

3.26" x 4.34" x 1.8"

[83 x 110.3 x 45.7] |

|

N |

SINGLE |

up to

±70° |

Analog mV |

3...6VDC |

65 |

Ø 1.46" x 0.45"

[Ø

37 x 12] |

|

NG360 |

SINGLE |

360° |

RS485 |

8...15VDC |

65 |

Ø 2.64" x 0.83"

[Ø

67 x 21] |

|

NGU |

SINGLE |

up to

±80° |

0...5VDC |

8...30VDC |

65 |

Ø 2.64" x 0.83"

[Ø

67 x 21] |

|

NGi |

SINGLE |

up to

±80° |

4...20mA |

8...30VDC |

65 |

Ø 2.64" x 0.83"

[Ø

67 x 21] |

|

NB3

|

SINGLE |

±10º |

Analog mV |

3...6VDC |

65 |

Ø 0.93" x 0.43"

[Ø 24 x 11] |

Back To Top

Accelerometer Sensors

|

SERIES |

AXIS |

Range |

Bandwidth |

output |

input supply |

dimensions |

|

B |

Single |

up to

±50g |

up to

550 Hz |

Analog mV |

3...6VDC |

Ø

0.93" x 0.43"

[Ø 24

x 11] |

|

BDK |

Single |

up to

±100g |

up to

1500 Hz |

Analog mV |

2...16VDC |

Ø

0.87" x 0.4"

[Ø 22

x 10,16] |

Back To Top

Sensor Packages

|

SERIES |

AXIS |

Range |

OUTPUT |

input supply |

IP rating |

Dimensions |

|

SB1i |

Single |

up to

±80°

or ±100g |

4...20mA |

8...30VDC |

65-67 |

3.86" x 2.52" x 1.42"

[98 x 64

x 36] |

|

SB1U |

Single |

up to

±80°

or ±100g |

0...5V |

8...30VDC |

65-67 |

3.86" x 2.52" x 1.42"

[98 x 64

x 36] |

|

SB2i |

Dual |

up to

±80°

or ±100g |

4...20mA |

8...30VDC |

65-67 |

3.86" x 2.52" x 1.42"

[98 x 64

x 36] |

|

SBG2U |

Dual |

up to

±80°

or ±100g |

0...5V

|

8...30VDC |

65-67 |

4.84" x 3.07" x 2.24"

[123 x

78 x 58] |

|

SBG3i |

Tri |

up to

±80°

or ±100g |

4...20mA |

8...30VDC |

65 |

4.84" x 3.07" x 2.24"

[123 x

78 x 58] |

|

SBL1i |

Single |

up to

±80° |

4...20mA |

8...30VDC |

65 |

7" x 7" x 3.94"

[178 x

178 x 100] |

|

SBL1S |

Single |

up to

±80° |

4...20mA,

0...5VDC,

relay |

8...30VDC |

65 |

7" x 7" x 3.94"

[178 x

178 x 100] |

|

SBS1U

SERVO |

Single |

±1° |

±5V |

12 or 24 VDC

|

65 |

3.86" x 2.52" x 1.42"

[98 x 64

x 36] |

Back To Top

ATEX or CSA (Hazardous Location) Sensor Packages

|

SERIES |

AXIS |

Range |

OUTPUT |

input supply |

Certification |

Dimensions |

|

SB2i |

Single or Dual |

up to

±80°

or ±100g |

4...20mA |

8...30VDC |

ATEX

or CSA |

3.86"

x 2.52" x 1.42"

[98 x 64 x

36] |

Back To Top

SUB SEA Sensor Packages

|

SERIES |

AXIS |

Range |

OUTPUT |

input supply |

IP rating |

Dimensions |

|

H6-Flex |

Single or Dual |

scalable |

4...20mA, RS485,

CAN |

11...30VDC |

68 |

3.26" x 4.34" x 1.8"

[83 x 110.3 x 45.7] |

|

XB |

Single or Dual |

up to

±80°

or ±100g |

4...20mA,

0...5VDC

|

8...30VDC |

68 |

6" x 4" x 2"

[153 x 102 x 51] |

Back To Top

LCD Display Packages

|

SERIES |

AXIS |

Range |

OUTPUT |

input supply |

IP rating |

Dimensions |

|

RDI |

Single or Dual |

up to

±70° |

LCD,

0...5VDC, RS232,

Switch |

8...30VDC |

65-66 |

4.53" x 3.54" x 2.21"

[115 x 90 x 56] |

Back To Top

Tilt Switches

|

SERIES |

AXIS |

Range |

trip setting |

OUTPUT |

input supply |

Dimensions |

|

RDI |

Single or Dual |

up to

±70° |

adjustable |

Open

Collector or Relay |

8...30VDC |

4.53" x 3.54" x 2.21"

[115 x 90 x 56] |

|

SlopeAlert™ |

Single or Dual |

up to

±45° |

factory

set |

Open

Collector or Relay |

8...30VDC |

2.87" x 2" x 1.5"

[72.9 x 50.8 x 38.1] |

|

SB1S |

Single |

up to

±80° |

adjustable |

Open

Collector |

8...30VDC |

3.86" x 2.52" x 1.42"

[98 x 64

x 36] |

|

SBL1S |

Single |

up to

±80° |

adjustable |

relay |

8...30VDC |

7" x 7" x 3.94"

[178 x

178 x 100] |

|

Digital Inclinometers: RDI LCD Display

Systems

|

Rieker’s RDI SERIES

of digital inclinometers is a complete angle monitoring and

early warning system. Available in both single or dual axis

packages, these units provide accurate tilt sensing in an

rugged, environmentally protected housing - temperature

compensation can be added to increase accuracy over

temperature. The RDI is the most flexible and multi-purpose

digital LCD display inclinometer system on the market today. |

Features and Options

(not all are available in certain

combinations)

-

Single and

Dual Axis

-

Remote Angle

Sensing Packages

-

Input Ranges

from ±4° to ±70°

-

Output

Options:

> Analog 0-5V

> Serial RS232

> Open

Collector Switch Outputs

> Relay Switch

(12VDC or 24VDC)

-

Power Supply

Options:

> 8-30VDC

non-regulated

> 9V Battery

> 110VAC or

240VAC Wall Adaptor

> Cigarette

Lighter Adaptor

-

LCD Displays

Angle in either:

> Degrees

> Percent

Grade

-

0.1° or 0.01°

Display Resolution

-

Relative Zero

Button

-

Minimum /

Maximum Angle Button

-

Up to 4 Open

Collector Switch Outputs

-

Adjustable

Trip Angle Settings

-

High

Current-Sink Capability

-

Lamp/Solenoid/Relay Drive

|

Applications

-

Equipment Roll

Over/Slope Warning

-

Platform

Leveling

-

Speaker &

Sound System Coordination

-

Pitch and Roll

Monitoring

-

Vehicle Tilt

Monitoring

-

Antenna

Positioning

-

Safe Corner

Speed Determination

-

Boom Angle

Indication

|

Industries

-

Aerial Work

Platforms

-

Cranes &

Derricks

-

Refuse & Dump

Trucks

-

Agricultural

Equipment

-

Excavators,

Graders, & Pavers

-

Drilling &

Mining Equipment

-

Fire & Rescue

-

Rough Terrain

Fork Lifts

-

Timber

Processors

|

|

Assignment of Axis |

|

Slip Indicators:

Aircraft Turn & Bank

|

Description

Rieker Inc has been

manufacturing slip indicators for the aircraft industry since

the early 1920's.

Over

the years, Rieker has produced a custom and stock slip

indicators used for general aviation, commercial, industrial,

and military applications. Today, our slip indicators provide

the most reliable and consistent roll in the industry. Over

the years, Rieker has produced a custom and stock slip

indicators used for general aviation, commercial, industrial,

and military applications. Today, our slip indicators provide

the most reliable and consistent roll in the industry.

Click here for additional

information: (external web links)

If you have an application

that requires custom gradiometer specifications,

please

contact us today with your requirements. One of our

engineers will be happy to speak with you. |

Model

1040: FAA Certified |

|

|

Definition:

A "slip" or "skid" or "bank"

indicator provides an economic method of determining the lateral

differential movement when banking or turning in an aircraft.

The bank or slip indicator consists of a curved glass tube

filled with a damping liquid in which a small ball rolls.

When the craft is horizontal, the

ball is located in the lowest part of the tube; as the craft

banks, gravity holds the ball at the lowest point as the tube

rotates from side to side. The tube can be calibrated to show

the angle of banking.

|

|

Tilt Switches: Open Collector & Relay

|

|

SlopeAlert Tilt Warning System |

RDI Series of Digital Inclinometers |

SB1S Inclinometer Package |

|

LOW COST Rough Terrain Tilt Switch |

LCD Display up to (4)

Open-Collector

Outputs |

0 to 5VDC Output + 2

Open-Collector Outputs |

Description

Rieker tilt indicating

instruments are utilized to provide a visual or audible alert to

warn operators of steep slopes and can be configured to disable

(or shut-off) equipment in the event of rollover - especially

useful for off-road construction equipment. These can be used in

any industry where a tilt warning is needed or required to

provide a safer condition.

Rieker tilt switches

vary from an economical approach if you are only looking for a

simple tip over warning (or "on/off" switch) as with the

SlopeAlert, to a constant feedback / visual readout of slope

angle with the versatile, semi-custom RDI Series of Digital

Inclinometers. Manufactured tough for off-road abuse and extreme

weather, all models offer easy to identify alert

characteristics. Click on the photos above for detailed

product information.

If you have an application

that requires custom gradiometer specifications,

please contact us today with

your requirements. One of our engineers will be happy to speak

with you. |

Definition

A tilt switch (also known as a

slope indicator

or inclinometer) generate an artificial horizon and measure

angular tilt (or slope) with respect to this horizon. The tilt

angle range is the range of desired linear output measured in

degrees. Common electrical outputs for inclinometers and tilt

sensors include, analog frequency or pulse width modulated,

analog voltage, digital (RS232) serial, and switched or alarm.

Other parameters to consider include operating temperature,

environment, shock, and vibration.

|

|

|

Electronic Sensors PDF Index

Experienced with the following or

Electrical/Mechanical Safety, EMI Immunity, MFG Process: CE,

CSA, MIL Spec, ISO

|

|

|

|

![]() 霍尔元件/霍尔IC/霍尔传感器

霍尔元件/霍尔IC/霍尔传感器![]()

![]() 编码器角度传感器总汇

编码器角度传感器总汇![]() 磁阻传感器

磁阻传感器![]() 电子指南针 电子罗盘陀螺仪/角速度传感器 磁传感器 加速度传感器 三维数字罗盘 二维数字罗盘 倾角传感器/模块三维电子罗盘

二维电子罗盘

双轴倾角仪

气压/海拔高度计

单轴倾角传感器

多角度测斜仪

电子指南针(二维罗盘)、三维罗盘、海拔高度、倾角等解决方案电子指南针传感器

压力传感器

加速度传感器

倾角传感器

运动表指南针方案

休闲系列指南针方案

车载指南针方案

穆斯林指南针方案

数码类指南针方案

电子罗盘方案

电子指南针 电子罗盘陀螺仪/角速度传感器 磁传感器 加速度传感器 三维数字罗盘 二维数字罗盘 倾角传感器/模块三维电子罗盘

二维电子罗盘

双轴倾角仪

气压/海拔高度计

单轴倾角传感器

多角度测斜仪

电子指南针(二维罗盘)、三维罗盘、海拔高度、倾角等解决方案电子指南针传感器

压力传感器

加速度传感器

倾角传感器

运动表指南针方案

休闲系列指南针方案

车载指南针方案

穆斯林指南针方案

数码类指南针方案

电子罗盘方案