| High Temperature Weldable Strain Gages - HBWANV

Gage Patterns for Dynamic Measurements |

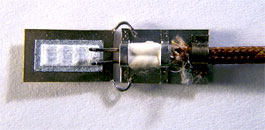

HBWANV Strain Gages are configured with a

Nichrome wire sensor bonded to a Hastelloy® X shim

using flame sprayed alumina.

These fatigue resistant gages are commonly used to

measure vibratory strain in extreme high temperature

environments on test components for automotive,

aerospace and power generation applications.

Maximum operating temperature at sensor:

1600°F (871°C)

Maximum operating temperature at cable:

(FG) Fiberglass Insulated - 900°F (482°C)

(MG) Mineral Insulated/Inconel Jacket - 1800°F

(980°C)

(CB) Ceramic Braid Jacket - 1800°F (980°C)

HBWANV-12-250-X-FG |

|

Standard Part Number |

Strain Type |

Max. Temp |

Gage Resistance (nominal) |

Gage Factor (nominal) |

Gage Length |

Instrumentation Cable |

Datasheet (pdf) |

|

HBWANV-12-250-X-FG |

Dynamic |

1600°F/sensor

900°F/cable |

120 Ohms |

2.0 |

.250" |

Fiberglass Insulated |

70-700 |

|

HBWANV-12-250-X-MG |

Dynamic |

1600°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.250" |

Mineral Insulated/Inconel

Jacket |

70-701 |

| HBWANV-12-063-X-MG |

Dynamic |

1600°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.063" |

Mineral Insulated/Inconel

Jacket |

70-702 |

| HBWANV-12-125-X-MG |

Dynamic |

1600°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.125" |

Mineral Insulated/Inconel

Jacket |

70-703 |

| HBWANV-12-125-X-FG |

Dynamic |

1600°F/sensor

900°F/cable |

120 Ohms |

2.0 |

.125" |

Fiberglass Insulated |

70-704 |

|

STANDARD GAGE CONFIGURATIONS CAN

BE CUSTOMIZED FOR INDIVIDUAL APPLICATIONS

CHOOSE OPTIONS FROM THE TABLE BELOW FOR HIGH

TEMPERATURE WELDABLE GAGES

|

|

GAGE RESISTANCE |

GAGE ALLOY |

| 12 |

120 Ohms |

H |

Hoskins™

(iron, chrome, aluminum) for static strain

measurements |

| 35 |

350 Ohms |

K |

K alloy (Evanohm)

(nickel, chrome, aluminum, iron) for static

strain measurements |

| |

|

NV |

Nichrome V (nickel,

chrome) for dynamic strain measurements |

|

SENSOR LENGTH |

PT |

Platinum-Tungsten for

dynamic strain measurements |

| 125 |

1/8" active grid |

|

|

| 250 |

1/4" active grid |

CONFIGURATIONS |

| 063 |

1/16" active grid |

QB |

Quarter Bridge - One

active element |

| |

|

HB |

Half Bridge - One

active element and one compensating element,

unstrained on coupon (available on H and K

type gages only) |

|

TEMP. COMPENSATION |

LHB |

Half Bridge - One

active element and one compensating element

without coupon |

| 0 |

Carbon |

FB |

Full Bridge - Two

sensing gages bonded to a shim and two

compensating gages bonded to an unstrained

compensating block |

| 6 |

6 ppm/°F |

R |

Rosette - Three active

elements placed at three different angles.

Most commonly 45° and 60° |

| |

|

|

|

PRE-CURVED SHIMS |

INSTRUMENTATION CABLE |

| Hoop

(Circumferential) |

CB |

Chromel/Alumel Wire -

Ceramic Braid Jacket - Maximum operating

temperature: 1800°F (980°C) |

| Axial

(Longitudinal) |

FG |

Fiberglass Wrapped

Stranded NCC Conductors - Maximum operating

temperature: 900°F (482°C) |

| |

|

MG |

MgO Mineral Insulated

Cable - Inconel Jacket - Maximum operating

temperature: 1800°F (980°C) |

|

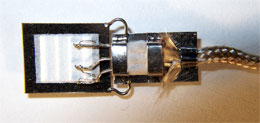

| High Temperature Weldable Strain Gages - HBWAPT

Gage Patterns for Dynamic Measurements |

HBWAPT Series strain gages are constructed with

a platinum-tungsten alloy that has excellent high

temperature oxidation resistance, and low, stable

temperature coefficients of resistance.

These high temperature strain gauges are an

excellent choice to measure the stress distribution

and fatigue life of turbine blades in rapidly

rotating turbo jet engines. Other uses include test

and failure analysis in many automotive and

aerospace applications.

Maximum operating temperature at sensor:

1900°F (1038°C)

Maximum operating temperature at cable:

(FG) Fiberglass Insulated - 900°F (482°C)

(MG) Mineral Insulated/Inconel Jacket - 1800°F

(980°C)

(CB) Ceramic Braid Jacket - 1800°F (980°C)

HBWAPT-12-250-X-CB |

|

Standard Part Number |

Strain Type |

Max. Temp |

Gage Resistance (nominal) |

Gage Factor (nominal) |

Gage Length |

Instrumentation Cable |

Datasheets (pdf) |

|

HBWAPT-12-250-X-CB |

Dynamic |

1900°F/sensor

1800°F/cable |

120 Ohms |

4.0 |

.250" |

Ceramic Braid |

70-715 |

|

HBWAPT-12-125-X-MG |

Dynamic |

1900°F/sensor

1800°F/cable |

120 Ohms |

4.0 |

.125" |

Mineral Insulated/Inconel

Jacket |

70-716 |

|

STANDARD GAGE CONFIGURATIONS CAN

BE CUSTOMIZED FOR INDIVIDUAL APPLICATIONS

CHOOSE OPTIONS FROM THE TABLE BELOW FOR HIGH

TEMPERATURE WELDABLE GAGES

|

|

GAGE RESISTANCE |

GAGE ALLOY |

| 12 |

120 Ohms |

H |

Hoskins™

(iron, chrome, aluminum) for static strain

measurements |

| 35 |

350 Ohms |

K |

K alloy (Evanohm)

(nickel, chrome, aluminum, iron) for static

strain measurements |

| |

|

NV |

Nichrome V (nickel,

chrome) for dynamic strain measurements |

|

SENSOR LENGTH |

PT |

Platinum-Tungsten for

dynamic strain measurements |

| 125 |

1/8" active grid |

|

|

| 250 |

1/4" active grid |

CONFIGURATIONS |

| 063 |

1/16" active grid |

QB |

Quarter Bridge - One

active element |

| |

|

HB |

Half Bridge - One

active element and one compensating element,

unstrained on coupon (available on H and K

type gages only) |

|

TEMP. COMPENSATION |

LHB |

Half Bridge - One

active element and one compensating element

without coupon |

| 0 |

Carbon |

FB |

Full Bridge - Two

sensing gages bonded to a shim and two

compensating gages bonded to an unstrained

compensating block |

| 6 |

6 ppm/°F |

R |

Rosette - Three active

elements placed at three different angles.

Most commonly 45° and 60° |

| |

|

|

|

PRE-CURVED SHIMS |

INSTRUMENTATION CABLE |

| Hoop

(Circumferential) |

CB |

Chromel/Alumel Wire -

Ceramic Braid Jacket - Maximum operating

temperature: 1800°F (980°C) |

| Axial

(Longitudinal) |

FG |

Fiberglass Wrapped

Stranded NCC Conductors - Maximum operating

temperature: 900°F (482°C) |

| |

|

MG |

MgO Mineral Insulated

Cable - Inconel Jacket - Maximum operating

temperature: 1800°F (980°C) |

|

| High Temperature Weldable Strain Gages - HBWAK

Gage Patterns For Static Measurements |

| HBWAK Series gages are constructed of

self-temperature compensated K alloy wire, and

bonded to a Hastelloy® X shim. Standard gages are

compensated for mild steel (6ppm/°F). K alloy is a

highly corrosion resistant alloy with superior

properties. Many of our customers utilize K-Alloy

gages for nuclear and fossil fuel applications as

well as renewable energy projects, where harsh

environments cause corrosion.

Maximum operating temperature at sensor:

650°F (343°C).

Maximum operating temperature at cable:

(FG) Fiberglass Insulated - 900°F (482°C)

(MG) Mineral Insulated/Inconel Jacket - 1800°F

(980°C)

(CB) Ceramic Braid Jacket - 1800°F (980°C)

HBWAK-35-250-X-FG |

|

Standard Part Number |

Strain Type |

Max. Temp |

Gage Resistance (nominal) |

Gage Factor (nominal) |

Gage Length |

Instrumentation Cable |

Datasheet (pdf) |

|

HBWAK-12-250-6-FG |

Static |

650°F/sensor

900°F/cable |

120 Ohms |

2.0 |

.250" |

Fiberglass Insulated |

70-705 |

|

HBWAK-12-250-6-MG |

Static |

650°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.250" |

Mineral Insulated/Inconel

Jacket |

70-706 |

|

HBWAK-35-250-6-FG |

Static |

650°F/sensor

900°F/cable |

350 Ohms |

2.0 |

.250" |

Fiberglass Insulated |

70-707 |

|

HBWAK-35-250-6-MG |

Static |

650°F/sensor

1800°F/cable |

350 Ohms |

2.0 |

.250" |

Mineral Insulated/Inconel

Jacket |

70-708 |

|

HBWAK-35-250-6-FG-HB |

Static |

650°F/sensor

900°F/cable |

350 Ohms |

2.0 |

.250" |

Fiberglass Insulated |

70-709 |

|

HBWAK-35-250-6-FG-SHIELD |

Static |

650°F/sensor

900°F/cable |

350 Ohms |

2.0 |

.250" |

3 Cond. NCC Shielded |

70-711 |

|

HBWAKR-12-250-6-MG |

Static |

650°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.250" |

Mineral Insulated/Inconel

Jacket |

70-713 |

|

STANDARD GAGE CONFIGURATIONS CAN

BE CUSTOMIZED FOR INDIVIDUAL APPLICATIONS

CHOOSE OPTIONS FROM THE TABLE BELOW FOR HIGH

TEMPERATURE WELDABLE GAGES

|

|

GAGE RESISTANCE |

GAGE ALLOY |

| 12 |

120 Ohms |

H |

Hoskins™

(iron, chrome, aluminum) for static strain

measurements |

| 35 |

350 Ohms |

K |

K alloy (Evanohm)

(nickel, chrome, aluminum, iron) for static

strain measurements |

| |

|

NV |

Nichrome V (nickel,

chrome) for dynamic strain measurements |

|

SENSOR LENGTH |

PT |

Platinum-Tungsten for

dynamic strain measurements |

| 125 |

1/8" active grid |

|

|

| 250 |

1/4" active grid |

CONFIGURATIONS |

| 063 |

1/16" active grid |

QB |

Quarter Bridge - One

active element |

| |

|

HB |

Half Bridge - One

active element and one compensating element,

unstrained on coupon (available on H and K

type gages only) |

|

TEMP. COMPENSATION |

LHB |

Half Bridge - One

active element and one compensating element

without coupon |

| 0 |

Carbon |

FB |

Full Bridge - Two

sensing gages bonded to a shim and two

compensating gages bonded to an unstrained

compensating block |

| 6 |

6 ppm/°F |

R |

Rosette - Three active

elements placed at three different angles.

Most commonly 45° and 60° |

| |

|

|

|

PRE-CURVED SHIMS |

INSTRUMENTATION CABLE |

| Hoop

(Circumferential) |

CB |

Chromel/Alumel Wire -

Ceramic Braid Jacket - Maximum operating

temperature: 1800°F (980°C) |

| Axial

(Longitudinal) |

FG |

Fiberglass Wrapped

Stranded NCC Conductors - Maximum operating

temperature: 900°F (482°C) |

| |

|

MG |

MgO Mineral Insulated

Cable - Inconel Jacket - Maximum operating

temperature: 1800°F (980°C) |

|

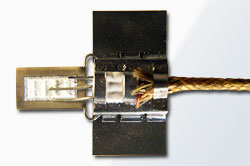

High Temperature Strain Gages - HBWAH Weldable

Gage Patterns

for Static Measurements |

| HBWAH Weldable Strain Gages are constructed of

an iron chrome aluminum alloy (Hoskins 875 ™)

providing high resistivity and very good oxidation

resistance. Recommended for high temperature

static measurements where a compensating gage, a

half bridge, or full bridge configuration is used.

Maximum operating temperature at sensor:

1800°F (980°C).

Maximum operating temperature at cable:

(FG) Fiberglass Insulated - 900°F (482°C)

(MG) Mineral Insulated/Inconel Jacket - 1800°F

(980°C)

(CB) Ceramic Braid Jacket - 1800°F (980°C)

HBWAH-12-125-6-FG-HB |

|

Standard Part Number |

Strain Type |

Max. Temp. |

Gage Resistance (nominal) |

Gage Factor (nominal) |

Gage Length |

Instrumentation Cable |

Datasheet (pdf) |

|

HBWAH-12-125-6-FG-HB |

Static |

1800°F/sensor

900°F/cable |

120 Ohms |

2.0 |

.125" |

Fiberglass Insulated |

70-722 |

|

HBWAH-12-250-6-FG-HB |

Static |

1800°F/sensor

900°F/cable |

120 Ohms |

2.0 |

.250" |

Fiberglass Insulated |

70-710 |

|

HBWAH-12-250-6-MG-HB |

Static |

1800°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.250" |

Mineral Insulated/Inconel

Jacket |

70-712 |

|

HBWAHR-12-125-6-MG-GP |

Static |

1800°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.125" |

Mineral Insulated/Inconel

Jacket |

70-714 |

|

HBWAHC-12-250-X-MG-HB |

Static |

1800°F/sensor

1800°F/cable |

120 Ohms |

2.0 |

.250" |

Mineral Insulated/Inconel

Jacket |

70-717 |

|

STANDARD

GAGE CONFIGURATIONS CAN BE CUSTOMIZED FOR

INDIVIDUAL APPLICATIONS

CHOOSE OPTIONS FROM THE TABLE BELOW FOR HIGH

TEMPERATURE WELDABLE GAGES

|

|

GAGE RESISTANCE |

GAGE ALLOY |

| 12 |

120 Ohms |

H |

Hoskins™

(iron, chrome, aluminum) for static strain

measurements |

| 35 |

350 Ohms |

K |

K alloy (Evanohm)

(nickel, chrome, aluminum, iron) for static

strain measurements |

| |

|

NV |

Nichrome V (nickel,

chrome) for dynamic strain measurements |

|

SENSOR LENGTH |

PT |

Platinum-Tungsten for

dynamic strain measurements |

| 125 |

1/8" active grid |

|

|

| 250 |

1/4" active grid |

CONFIGURATIONS |

| 063 |

1/16" active grid |

QB |

Quarter Bridge - One

active element |

| |

|

HB |

Half Bridge - One

active element and one compensating element,

unstrained on coupon (available on H and K

type gages only) |

|

TEMP. COMPENSATION |

LHB |

Half Bridge - One

active element and one compensating element

without coupon |

| 0 |

Carbon |

FB |

Full Bridge - Two

sensing gages bonded to a shim and two

compensating gages bonded to an unstrained

compensating block |

| 6 |

6 ppm/°F |

R |

Rosette - Three active

elements placed at three different angles.

Most commonly 45° and 60° |

| |

|

|

|

PRE-CURVED SHIMS |

INSTRUMENTATION CABLE |

| Hoop

(Circumferential) |

CB |

Chromel/Alumel Wire -

Ceramic Braid Jacket - Maximum operating

temperature: 1800°F (980°C) |

| Axial

(Longitudinal) |

FG |

Fiberglass Wrapped

Stranded NCC Conductors - Maximum operating

temperature: 900°F (482°C) |

| |

|

MG |

MgO Mineral Insulated

Cable - Inconel Jacket - Maximum operating

temperature: 1800°F (980°C) |

|

| |

| |

![]() 称重传感器及称重变送器称重仪表总汇

称重传感器及称重变送器称重仪表总汇 ![]() 应变片选择指南

应变片选择指南 ![]() 称重/测力/力传感器/仪器

称重/测力/力传感器/仪器![]() 称重控制仪表

称重控制仪表

![]() 张力/重力/荷重/重量传感器

张力/重力/荷重/重量传感器![]() 全球称重产品总汇

全球称重产品总汇