|

|

Solid State Gas Sensors

Products and Services

Synkera's products are based on nano- and

microstructured materials and advanced methods for their

integration into functional devices. We offer three

main product groups:

The

first is a broad group of chemical sensors

and related devices. Synkera's sensor

technology is bridging the gap between the low

cost of traditional solid-state sensors and

the performance of liquid electrolyte

electrochemical sensors.

The

second product group is comprised of membranes

for filtration and separation in gases and liquids and

related applications. Our membranes are based on self-organized

nanoporous ceramic that supports highly controllable

nanoscale morphology and composition, enabling high

performance, reliable and cost-effective solutions in a

diverse range of applications.

The

third product group includes a broad range of NanoCeramic-based

offerings with performance and benefits engineered at

the nano/microscale. These include nanotemplates,

substrates for bioanalysis, ceramic microcomponents,

functional coatings and nanocomposites.

Electronic Modules

Synkera now provides two

types of modules for testing and evaluation of our

various sensor product lines:

Our latest

MikroKera™ Ultra Module (P/N 9100) features

all-digital input and output, and even wireless

connection by Bluetooth. This module can be used for

quick and easy setup and evaluation of our UltraKera™

sensor product line (module purchase includes 1 sensor).

Our original set of electronic modules, encompassing P/N

901 to 917, feature analog input and output, and can be

used to operate both our

ProKera™ and

MikroKera™ sensors. These modules require a 9-12

VDC input and provide a 0-5 VDC output. These modules

allow for adjusting the input voltage to the heater,

zeroing the sensor, and setting gain. To place an order

for analog modules, visit our

online store.

UniKera Ceramic Membranes

Standard

Ceramic Membranes Standard

Ceramic Membranes

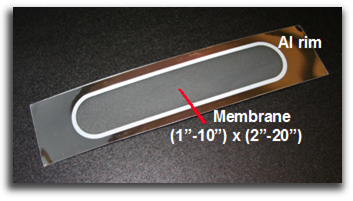

Synkera's

largest 11" x 18" AAO membrane with aluminum rim. Synkera's

largest 11" x 18" AAO membrane with aluminum rim.

Synkera offers three different types of membranes:

UniKera™ Standard,

UniKera™ UF and

nanocomposite. Unique features and

performance of these products are derived from the

controllable nanoscale morphology and composition of the

active layer(s), as well as chemical and mechanical

properties of anodic

aluminum oxide. These membranes are produced using

our unique capabilities in extremely high precision

nanoscale engineering of materials architecture and

composition, following strict quality-control

procedures.

Synkera offers a range of standard products, as well as

many custom options for each membrane type. Please

follow the links below for further details or go

directly to the quote/info

forms to request a quote or to place an order.

Our

symmetric membranes feature uniform and aligned

cylindrical nanopores, ensuring consistent pore

diameter and pore density throughout the thickness of

the membrane.

Our

monolithic asymmetric membranes feature a

support layer with large pores and a

very thin (sub-0.5 µm) active layer with pores

tunable in the 5-200 nm range. This allows for precise

size-based separation, while maintaining high permeance

and low fouling. These features enable significant

performance benefits in liquid separation, such as

microfiltration, ultrafiltration and nanofiltration.

Our

nanocomposite membranes feature very thin

nanocomposite active layers intimately embedded

within the pores of anodic alumina to enable high

permeance and selectivity to target molecules and

outstanding reliability in operating conditions.

UniKera Standard Membranes

Pricing

Synkera offers symmetric monodisperse nanoporous ceramic

membranes that are produced from nanoporous anodic

aluminum oxide (AAO). This type of membrane features

a symmetrical nanoporous architecture with uniform

cylindrical pores penetrating the entire thickness of

the membrane, and are characterized by a high degree of

pore ordering and narrow pore size distribution

(standard deviation is typically better than 8%, and in

some cases is as low as 5%).

Synkera's symmetric membranes have superior mechanical

and thermal stability far exceeding that of anodic

alumina membranes from other suppliers. As-prepared AAO

membranes are amorphous, but could be converted to

nanocrystalline gamma and alpha-alumina phases which

further enhances the membrane's chemical and thermal

stability. Synkera offers several membrane

heat-treatment options for operating temperatures up to

1000°C.

The range of currently available membrane specifications

is summarized in the table below. We maintain an

inventory of membranes with standard specifications.

Most of our ceramic membranes could be ordered with a

pore diameter in the range from 10 to 150 nm, and the

thickness from 15 to 100 microns. For more details on

this product, please see the AAO

Technology Profile.

To order membranes, inquire on the product availability

for non-standard specifications, and/or get feedback on

your desired applications, please fill out our Info/Quote

Request Form.

|

Parameter |

Standard |

Custom |

|

Pore Diameter,

nm (SD 7-10%) |

18 |

35 |

55 |

80 |

100 |

150 |

10-200 |

|

Pore Density,§

cm-2 |

6·1010 |

1·1010 |

6·109 |

2·109 § |

2·109,§

9·108 |

2·109,§

9·108 |

2·1011 - 9·108 |

|

Pore Period,§ nm |

44 |

94 |

143 |

243 § |

243,§

367 |

243,§

367 |

20 - 367 |

|

Estimated Porosity,§

% |

15 |

13 |

13 |

10 § |

15,§

7 |

35,§

15 |

10% to 50% |

|

Thickness,

µm (± 2%) |

50 and 100* |

15-150 ± 2% |

|

Format / Size |

round shape: 13, 25,

47 mm

square shape: 10x10 mm |

custom shapes, up to 120 mm in

size |

|

Operating Temperature |

No heat treatment:

· up to 500°C (depending on the environment)

Heat

treatment options:

· OPTION 1: ≤ 700°C (amorphous)

· OPTION 2: ≤ 900°C (γ-alumina)

· OPTION 3: ≤ 1000°C (γ/ α - alumina) * |

up to 1000°C

(γ/ α - alumina) * |

|

Availability |

4-6 weeks if not in-stock |

Varies |

§ Standard pore density, period and porosity values

for 80, 100 and 150 nm pore sizes.

* Heat treatment option 3 is not available for 13 and

18 nm pores

Based

on our expertise in materials science, nano- and

microfabrication, and using this featured AAO membrane

as a platform, Synkera is developing a portfolio of

symmetric membrane products for the following

applications:

UniKera UF Membranes

Asymmetric

Membranes Asymmetric

Membranes

Pricing

Synkera offers

asymmetric ceramic membranes for liquid (such as nano-

and ultrafiltration) and gas filtration, as well as for

other applications. As many of our products, these

membranes are made from monolithic nanoporous

anodic aluminum oxide (AAO)

and are characterized by very uniform pores in the

active layer. The membranes also feature a novel

architecture with a very thin and uniform active layer.

Such attributes address the need for membranes with

improved selectivity, higher permeance, reduced fouling

and better durability.

Structure

of Synkera Asymmetric Membranes Structure

of Synkera Asymmetric Membranes

Membrane

Features & Benefits

-

Narrow pore size distribution (standard deviation is

typically better than 10%) and sharp molecular

weight cutoff (MWCO)

-

Pore diameter and MWCO values are highly

reproducible

-

High pore density in a very thin active layer and

large pores and high porosity in the support layer

enable water permeance in the range of 5•10-8

cm/s/Pa

-

Smooth surface and uniform pores reduce fouling

-

Made of non-toxic and biocompatible alumina with no

extractables and no product contamination

-

Good mechanical durability and resistance to

abrasion

-

Immune to organic solvents and radiation

-

Reliable compression sealing using an optional

aluminum rim

-

Planar membranes available in a variety of standard

and custom sizes and shapes. Scalable up to 1 sq.

ft.

As-prepared membranes contain amorphous boehmite phase,

which is suitable for short (<3 hrs) exposure to aqueous

solutions. Polycrystalline membranes, composed from

gamma and alpha-alumina phases with significantly

enhanced chemical and thermal stability, are also

available. For additional information, please see Technology

Profile for this product.

Ordering

The range of currently offered membrane specifications

is summarized in the table below. We maintain an

inventory of membranes with standard specifications. To

order membranes, inquire on the product availability for

non-standard specifications, and/or get feedback on your

desired applications, please fill out our Info/Quote

Request Form.

|

Parameter |

Standard

|

Custom |

|

Base

Layer |

Pore diameter,

nm (SD 7-10%) |

150 - 200 |

same as standard

|

|

Pore density, cm2 |

1x109 |

|

Porosity, % |

30 - 40 |

|

Active

Layer |

Pore diameter,

nm (SD 7-10%) |

2 - 4 |

4 - 6 |

8 |

13 |

18 |

150 |

2-20 |

|

Pore density, cm2 |

7x1012 |

2x1012 |

3x1011 |

1x1011 |

5x1010 |

1x109 |

2x1011

to 7x1012 |

|

Porosity, % |

10 to 20,

depending on port diameter |

up to 50 |

|

Overall

Structure |

Thickness, µm

(±2%) |

50 |

|

|

Format / Size |

round shape: 13, 25 mm |

custom shapes, up

to 120mm in

size |

|

Operating Environment |

AS IS:

aqueous: short exposure (≤3hr.), pH 6 to 8

non-aqueous:

indefinite for non-corrosive

gases: up to

500°C for non-corrosive

HEAT TREATED:

≤700°C (amorphous), Option 1

≤900°C

(γ-alumina), Option 2

≤1000°C

(γ/α alumina), Option 3 |

contact us if you

have any questions on your application

|

|

Availability |

2

-3 weeks if not in stock |

Nanocomposite Membranes

Energy-efficient hydrogen generation and purification is

needed for many clean energy applications and industrial

processes. Synkera is developing novel metal/ceramic

hydrogen separation membranes that target breakthrough

performance and reliability in a broad range of

operating conditions and offer significant cost savings

at the system level. These benefits, enabled by

patent-pending nanoengineered membrane composition and

architecture, provide significant competitive advantages

for many point-of-use hydrogen separation and

purification applications. Synkera is commercializing

its hydrogen-related products, including hydrogen

separation membranes and hydrogen sensors, via its

subsidiary HyGenera

LLC.

The

key membrane features and related user benefits are

-

Nanocomposite

metal/ceramic active layer with permeance exceeding

that of 10 µm thick Pd alloy foil membranes.

-

Low defect density,

high permselectivity.

-

Mechanical

reliability, resistance to abrasion.

-

Excellent

resistance to temperature and pressure cycling,

immune to embrittlement.

-

Planar membranes of

flexible size and format.

-

Al rim to support

reliable and low-cost compression sealing.

-

Significant

reduction in the cost of membrane modules and

separation systems in comparison with Pd foils or

supported films.

Download Technology

Profile for more information on hydrogen separation

membranes.

Hydrogen

flux vs. differential pressure for 1" laboratory

prototype. Hydrogen

flux vs. differential pressure for 1" laboratory

prototype.

Status

To

date, hydrogen permeance of up to 1.5 mmol/m2/s/Pa0.5

at 400 °C and selectivity up to 3000 were demonstrated

in laboratory prototypes. Membranes sustain repeated

temperature (75 to 450°C) and pressure (0 to 100 psig)

cycling in 100% hydrogen without loss of performance.

With support from NSF SBIR program, Synkera is scaling

Gen-1 membranes (~1 mmol/m2/s/Pa0.5)

to produce prototypes sized at 30 cm2 and 725

cm2. Concurrently, we are validating membrane

performance and reliability in select process streams (reformate

and WGS).

Temperature

cycling performance of Synkera membrane (100% H2,

60 psig). Temperature

cycling performance of Synkera membrane (100% H2,

60 psig).

Partnership Development

Customers and partners are being sought for evaluating

these membranes in new membrane systems and

applications. Areas of interest include fuel cells,

point-of-use and distributed purification, as well as

industrial processes. To request additional information

and to discuss this further, please e-mail us at

UniKera Membranes

Our UniKera™ line of ceramic disc membranes are used

for:

Our membranes feature configurable specifications in

a wide range of options:

|

Parameter |

Range |

|

Pore Diameter,

nm (SD 7-10%) |

10-200 |

|

Thickness,

µm (± 2%) |

15-150 |

|

Format / Size |

Round, square, custom. Up to 120 mm in

size |

|

Operating Temperature |

up to 1000°C |

|

Availability |

4-6 weeks, depending on stock |

Descriptions and specifications of our two membrane

types are provided below. In addition, follow these

links for further info:

UniKera™ Standard Membranes

Synkera offers ceramic

membranes that feature uniform cylindrical pores

penetrating the entire thickness of the membrane, and

are characterized by a high degree of pore ordering and

narrow pore size distribution. UniKera™

membranes have superior mechanical and thermal

stability far exceeding that of anodic alumina membranes

from other suppliers. UniKera™ membranes can be

converted into nanocrystalline gamma and alpha-alumina

phases, to further enhane chemical and thermal

stability. Synkera offers several membrane

heat-treatment options for operating temperatures up to

1000°C.

UniKera™ UF Membranes

These membranes feature a novel architecture with a very

thin and uniform active layer, and are characterized by

very uniform pores in the active layer. UniKera™

UF membranes address the need for membranes with

improved selectivity, higher permeance, reduced fouling

and better durability.

Structure

of Synkera Asymmetric Membranes Structure

of Synkera Asymmetric Membranes

NanoCeramics

Anodic

Alumina Nanotemplate Anodic

Alumina Nanotemplate

Micromachined

Ceramic Micromachined

Ceramic

Synkera offers several product lines based on our nano/microfabrication

technologies. Unique features and performance of

these products are derived from precisely controlled

nanoscale morphology, composition chemical and

mechanical properties of anodic

aluminum oxide, our unique processes for ceramic

micromachining and ability to conformally coat very high

aspect ratio nanopores with different materials.

Synkera offers a selection of standard products, and

also welcomes inquiries for custom manufacturing. Please

follow the links below for further details.

Synkera offers a broad range of anodic

alumina-based nanotemplates of three distinct

formats: AAO on Al foil, AAO integrated on Si, glass or

other substrates, and free-standing AAO. These products

feature excellent pore diameter uniformity and have been

used by a number of research groups worldwide for

deposition of uniform and ordered arrays of

nanostructures (nanoparticles, nanowires, nanorods,

nanotubes, etc) as well as for synthesis of advanced

nanocomposites.

Synkera offers custom ceramic microcomponents

from nanoporous alumina that can accommodate

diverse application ranging from high temperature gas

sensing to in-vivo bioanalysis. Our

process combines features of both surface- and bulk–

like micromachining and can support a broad range of

designs, including high-resolution, high aspect ratio

structures and elements of 3-D designs.

We

offer nanoporous ceramic substrates for various

life science applications. The substrates

feature excellent biocompatibility, 3-D nanoporous

architecture and are available in several formats to

support a variety of analysis modes.

Conformal nano-scale coatings on high aspect

ratio surfaces are available for all of our AAO-based

membrane and nanotemplate products as well as on

customer-provided samples.

UniKera NanoTemplates

Synkera offers a broad range of anodic alumina-based

nanotemplates of three distinctly different

architectures:

-

AAO Nanotemplates attached to Al foil (see

specifications below).

-

Free-standing AAO nanotemplates (specifications same

as UniKera™

standard membranes).

-

Nanotemplates on non-Al substrates, such as Si or

glass (

email us

This email address is

being protected from spambots. You need JavaScript

enabled to view it.

for availability).

Most of our AAO nanotemplates and nanoporous

membranes could be ordered with pore diameter in 10-100

nm range. They are characterized high degree or pore

ordering, narrow pore size distribution (standard

deviation is typically better then 10%, and in some

cases as low as 5%), as well as uniform pore diameter

across the entire AAO thickness. For free-standing

nanotemplates, standard heat-treatment options include

annealing of the originally amorphous AAO to

nanocrystalline gamma or alpha-alumina phase, which

further enhances nanotemplate's chemical and thermal

stability.

The range of currently available specifications for

nanotemplates on Al and other substrates is summarized

in the table; specifications for free-standing AAO

nanotemplates are listed under

UniKera™ standard membranes.

To order nanotemplates, inquire on the availability of

custom products with non-standard specifications, and to

discuss your specific applications, please fill out our Info/Quote

Request Form.

|

Parameter |

AAO on Al * |

AAO on

non-Al substrates**

(custom only) |

|

Standard |

Custom |

|

Pore diameter,

nm (SD 7-10%) |

13 |

18 |

35 |

55 |

73 |

80 |

100 |

150 |

10 - 200 |

10 - 35 |

|

Pore Density,§

cm-2 |

1·1011 |

6·1010 |

1·1010 |

6·109 |

3·109 |

3·109,

2·109 §

|

3·109,

2·109,§

9·108 |

2·109,§

9·108 |

2·1011 - 9·108 |

1·1011 - 1·1010 |

|

Pore Period,§ nm |

32 |

44 |

94 |

143 |

193 |

193, 243 §

|

193,

243,§

367 |

243,§

367 |

20 - 367 |

20 - 107 |

|

Estimated

Porosity,§ % |

15 |

15 |

13 |

13 |

13 |

16,

10 §

|

24,

15,§

7 |

35,§

15 |

10 - 30 % |

10 - 30 % |

|

AAO Thickness,

µm (± 2%)

|

0.5, 5 and 50

|

5 and

50 |

0.1 - 150 |

0.1 - 5,

per Al film thickness |

|

Format / Size * |

square shape; 10x10 mm and 65x65

mm;

AAO on one or both sides of Al substrate * |

from 65x65 mm to 150 mm *‡ |

per customer substrate size and format

(up to 150 mm)

|

|

Operating Temperature |

No heat

treatment: up to 500°C

(depending on the environment)

Heat treatment option 1:

500°C

|

N / A |

|

Availability

|

3-4 weeks if not in-stock |

4-6 weeks |

4-6 weeks |

* AAO on one side of

the Al substrates is only available for thicknesses 0.5

and 5 µm.

** Requires Al films on Si, glass or other substrates to

be provided by the customer; e-mail for requirements.

§ Standard pore density, period and

porosity values for 80, 100 and 150 nm pore sizes

‡ Custom AAO on Al nanotemplates can be cut into smaller

size pieces per customer requirements

Some of the applications for the featured

nanotemplates and nanomembranes include:

Ceramic Microcomponents

Micromachined

ceramic Micromachined

ceramic

Demand for robust and resilient microcomponents

increases with the continuous trend towards

miniaturization. Many existing and new applications

require microcomponents from refractory materials to

obtain requires mechanical properties and ensure

stability in harsh environments. Although silicon

carbide, silicon nitride, and sapphire have been

identified as candidates for this type of MEMS,

combination of high cost, poor manufacturability, and

very limited designs stimulates the development of new

technologies.

Synkera Technologies addresses these needs using its ceramic

micromachining technology to produce microcomponents

from nanoporous alumina with the following features:

-

Chemically &

thermally robust ceramic microstructures

-

Multilevel,

surface- and bulk-like micromachining

-

High aspect ratio

(1:100); high resolution (2-3 µm)

This

technology enables very flexible designs and provides

numerous opportunities for development of novel ceramic

microcomponents and microdevices:

Substrates for Bioanalysis & Bioarrays

Bioarrays enable high-throughput molecular analyses and

have aided tremendous advances in life science research.

Further increasing bioarray sensitivity and

reproducibility will enable broader acceptance and

standardization for more demanding settings, such as

clinical diagnostics. Furthermore, increasing the range

of options in bioarray substrates and surface

chemistries - key elements in performance - will enable

greater design flexibility and novel applications,

especially with respect to protein and glycan-based

arrays.

Synkera is developing novel bioarray and bioanalysis

substrates that can significantly enhance bioarray

performance through a unique 3-D nanoporous architecture

that features high specific surface area and flexible

surface chemistry. These substrates can serve as drop-in

replacement for current glass-based arrays as well as

support novel bioarrays and assays.

Substrate features and

benefits

-

High probe capacity

due to high surface area, 3-D architecture of

nanoporous ceramic substrate.

-

Ability to vary the

capacity via control of the pore depth.

-

Ability to block

large molecules interference based on size

exclusion.

-

High-resolution

spotting due to wicking into vertically aligned

pores, eliminating lateral spreading.

-

Tailorable surface

chemistry for various attachment options and

minimized non-specific background binding.

-

Optional

flow-through architecture for increased sampling

rate and fast analysis of low concentration targets.

-

Micromachinable for

integration with advanced microfluidics

(lab-on-a-chip).

Status

Left:

8 mm x 35 mm array substrates with 150 nm pores.

Right: representative microchips for bioanalysis Left:

8 mm x 35 mm array substrates with 150 nm pores.

Right: representative microchips for bioanalysis

Left:

SEM of ceramic array substrate with 50 nm pores.

Right: array of microwells in nanoporous ceramic

substrate. Left:

SEM of ceramic array substrate with 50 nm pores.

Right: array of microwells in nanoporous ceramic

substrate.

Leveraging its extensive capabilities in developing

numerous products based on this

material platform, Synkera completed initial

development of Gen-1 bioarray substrates. Prototypes are

being evaluated for fluorescence-based assays and other

bioanalysis applications. You can see our current

offerings and get further info by filling out an Info/Quote

Request form.

Partnership Development

|

Synkera's

largest 11" x 18" AAO membrane with aluminum rim.

Synkera's

largest 11" x 18" AAO membrane with aluminum rim.

Asymmetric

Membranes

Asymmetric

Membranes Structure

of Synkera Asymmetric Membranes

Structure

of Synkera Asymmetric Membranes

Hydrogen

flux vs. differential pressure for 1" laboratory

prototype.

Hydrogen

flux vs. differential pressure for 1" laboratory

prototype. Temperature

cycling performance of Synkera membrane (100% H2,

60 psig).

Temperature

cycling performance of Synkera membrane (100% H2,

60 psig). Structure

of Synkera Asymmetric Membranes

Structure

of Synkera Asymmetric Membranes Anodic

Alumina Nanotemplate

Anodic

Alumina Nanotemplate

Left:

8 mm x 35 mm array substrates with 150 nm pores.

Right: representative microchips for bioanalysis

Left:

8 mm x 35 mm array substrates with 150 nm pores.

Right: representative microchips for bioanalysis Left:

SEM of ceramic array substrate with 50 nm pores.

Right: array of microwells in nanoporous ceramic

substrate.

Left:

SEM of ceramic array substrate with 50 nm pores.

Right: array of microwells in nanoporous ceramic

substrate.