Performance Data

Evaluate our MaxSonar Ultrasonic Sensors

Our product lifetime test was setup in an industry standard way. To facilitate reasonable test duration, the test temperature of 85°C allowed an acceleration factor. For the purposes of this test, the Arrhenius model was used.

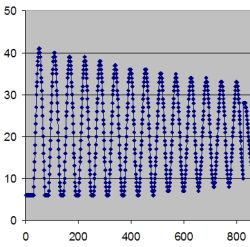

The test demonstrates how accurately our sensors measure distance, and takes into account the part-to-part consistency, the full operating voltage range, and the reading-to-reading stability. The measured accuracy results speak for themselves. As CEO of MaxBotix Inc., I could not be more pleased with these test results.

MaxBotix Inc., sensors have been successfully used on a number of multi‑copters. (Multi‑copters are also called UAVs, rotorcraft, quadrotor helicopters, or quadcopters.) Even so, many users have had issues getting the sensors to operate reliably. Sensor operation during flight on a quad‑copter is a challenging environment for an ultrasonic sensor to operate reliably. The most obvious issue is the amount of wind turbulence the ultrasonic wave must travel though. Adding to this acoustic noise is the noise the propellers generate.

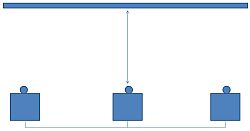

MaxBotix Inc., has recently tested operation of our MB7360 HRXL‑MaxSonar‑WR in a multi-sensor environment. The testing was conducted from 11/15/2012 to 11/19/2012.

All the test data (about 7.5mil. data points) gathered show there to be no interference from multi-sensor operation for the MB7360 in this test setup.

MaxBotix Inc., thanks guest writer Tim Gallagher who shares his experience with the MB7369 while transporting heavy equipment.

MaxBotix Inc., sensors have been successfully used in extreme duty conditions. Large multi-axle trailers, which are used to transport wind energy equipment across the country, hydraulically adjust the ride height of their payload throughout their journey to meet varying conditions. The HRXL‑MaxSonar‑WR sensor series withstand the extreme environmental conditions of these trips, and power through the extreme road noise and wind conditions.

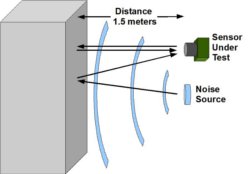

Recently, some of our users in the UAV community have been asking questions about the difference in noise tolerance between our LV-MaxSonar-EZ products and our XL-MaxSonar-EZ/AE products. As a result, MaxBotix Inc., felt that it would be a good idea to provide our users with test data for each of our current sensors ability to reject acoustic noise sources.

MaxBotix Inc., wanted to provide a sensor that was better than the others. Range stability was the primary goal. All other goals were either required to meet this primary goal, or were secondary goals.